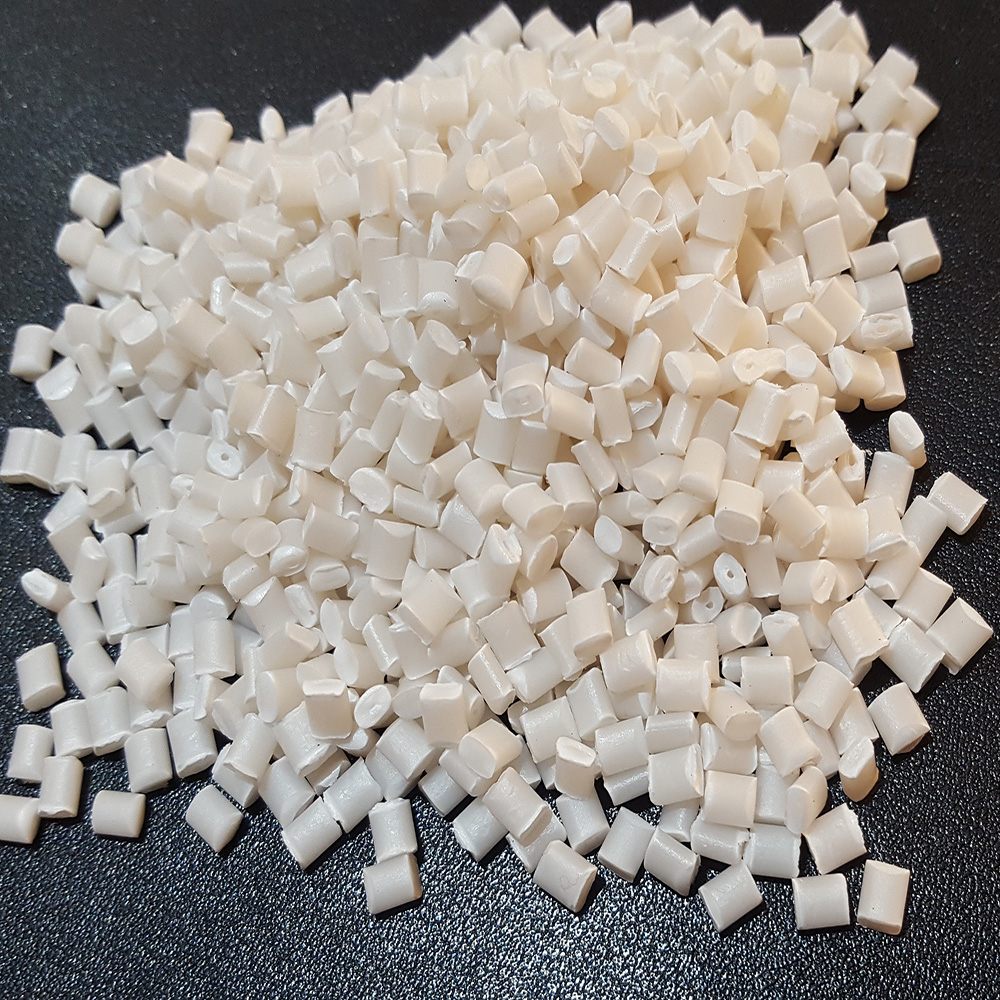

This material is one of the most widely used and diverse thermoplastic polymers used in various industries and is obtained from the polymerization of ethylene. It can be produced in a linear or branched form depending on its molecular structure, which creates different types such as HDPE, LDPE, LLDPE and UHMWPE. The melting temperature of polyethylene varies depending on its type, and these differences have a direct impact on the application of polyethylene. By understanding what polyethylene is and how its structure and melting temperature affect its physical and chemical properties, this material can be best used in the production of various products such as pipes, packaging films, industrial parts and sports equipment.

What is polyethylene?

Types of polyethylene

Ultra-high molecular weight polyethylene (UHMWPE)

This material has long, linear chains that give it high resistance to impact, abrasion, hardness, and compressive fracture. This type of polyethylene, with difficult processability, is used to produce strong fibers that replace Kevlar in bulletproof vests. Large sheets of UHMWPE can be used as a replacement for ice skating rinks. These applications show what polyethylene is and why it has important applications in certain industries.High Density Polyethylene (HDPE)

High Density Polyethylene (HDPE) is a linear, stiffer, branched polyethylene that has high tensile strength. This type of polyethylene is produced by polymerization at low pressure and temperature. The mechanical properties of HDPE allow it to be used in larger shapes and applications such as sheet materials in tanks and column insulation, and the use of heat welding to join this material is also common.Cross-Linked Polyethylene (PEX or XLPE)

This type of cross-linking (PEX or XLPE) is converted into a thermoset polymer by creating cross-links in the polymer structure, increasing its density and improving its mechanical properties at high temperatures. This type of polyethylene is used in drinking water piping and insulation of medium and high voltage electrical cables. PEX polyethylene is also used in hot water pipes and molded parts.Medium-density polyethylene (MDPE)

This type has higher impact and stress-strain resistance than HDPE and, due to its high chemical resistance, is commonly used in gas pipes and fittings, packaging, carrier bags, and bottle caps.Linear low-density polyethylene (LLDPE)

This polymer is obtained by copolymerizing ethylene with short-chain α-olefins such as 1-butene or 1-hexene and is used to make plastic films such as freezer bags. LLDPE has higher tensile, impact, and puncture resistance than LDPE, and can produce blown films with thinner thicknesses and better strength.Lightweight Low Density Polyethylene (LDPE)

This type is produced under high pressure and temperature, usually using vinyl free radical polymerization, and is used for piping and packaging due to its transparency, flexibility, and expandability. Its chemical resistance is lower than that of HDPE and polypropylene, but it is still resistant to many acids and alkalis.Very light polyethylene (VLDPE)

VLDPE has a linear structure with high levels of short-chain branches and is produced by copolymerization of ethylene with short-chain α-olefins or using metallocene catalysts. It is used in the production of hoses and pipes, ice packs and frozen foods, food packaging, and also as impact modifiers in combination with other polymers.

Applications of polyethylene

Polyethylene is used in the production of household appliances, for the manufacture of bottles, kitchen utensils, plastic parts for household appliances, and toys.

Melting temperature of polyethylene

- HDPE has a melting point of around 130-140°C and, due to its linear and crystalline structure, has high strength and toughness, making it suitable for industrial applications such as the production of polyethylene pipes, tanks and plastic parts.

- LDPE has a melting point of around 105-115°C and has a branched structure that makes it softer and more flexible.

- LLDPE has a melting point similar to or slightly higher than LDPE and offers a combination of strength and flexibility due to its linear structure with short branches.

- MDPE has a melting point of around 120-130°C and has properties between HDPE and LDPE.

- UHMWPE has a melting point similar to HDPE, but due to its very long molecular chains, it has special physical properties such as extremely high strength and abrasion resistance. Provides.

Chemical structure of polyethylene

Summary

As one of the most widely used thermoplastic polymers, polyethylene plays a vital role in various industries with its diversity in structure and melting temperature. A precise understanding of what polyethylene is and the types of polyethylene and their applications will allow us to optimally use this material in the production of various products.From durable pipes and tanks to flexible packaging films, polyethylene’s melting point and molecular structure have a direct impact on the physical and chemical properties of this polymer. Ultimately, this material, with its unique characteristics, has a special place as a basic material in industrial and consumer products.

Frequently Asked Questions

- How does the structure of polyethylene affect its properties?

- Is polyethylene recyclable?

- Can polyethylene be copolymerized with other monomers?

- How does the melting point of polyethylene affect its properties?